How 3D Printing is Creating Future for Healthcare Graduates

Estimated reading time: 26 minutes

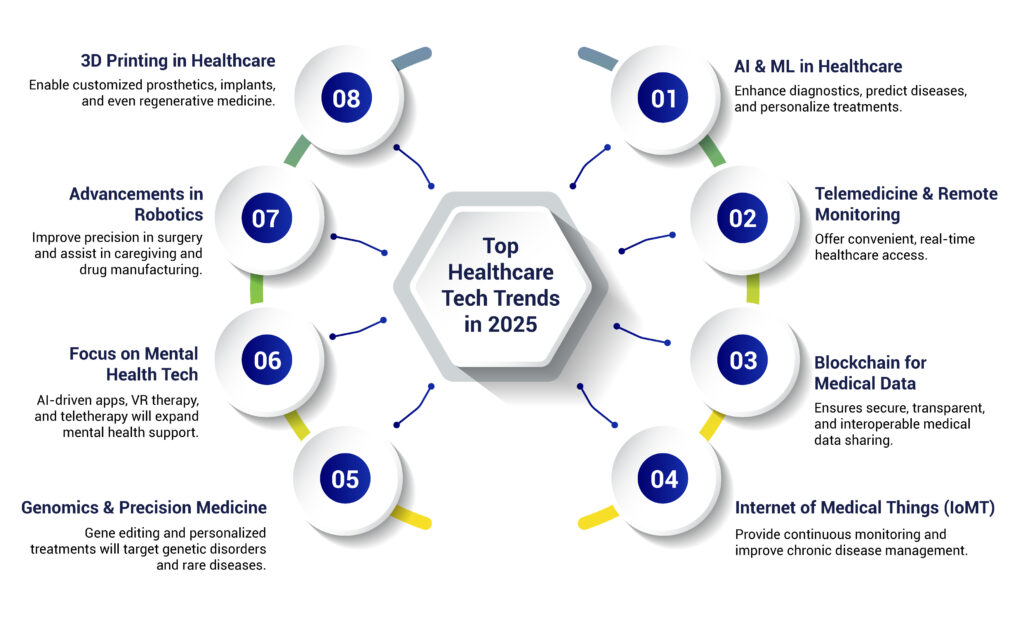

3D printing technology is rapidly transforming the healthcare landscape, creating a wealth of new opportunities and possibilities for healthcare graduates, students, and professionals alike. Originally developed and primarily used as a tool for manufacturing prototypes and basic models, 3D printing has evolved significantly and now plays crucial and multifaceted roles across various aspects of healthcare.

These roles include enhancing medical education by providing realistic anatomical models, improving patient care through customized implants and devices, advancing prosthetics with highly personalized designs, facilitating precise surgical planning, and accelerating biomedical research with innovative experimental tools and materials.

The integration of 3D printing technology in healthcare is opening up a wide range of exciting and innovative career paths, offering numerous competitive advantages for recent graduates from medical, nursing, biomedical engineering, and allied health programs. This advancement is transforming traditional roles and creating new opportunities for professionals entering the healthcare field.

This groundbreaking and revolutionary technology not only significantly enhances patient outcomes but also empowers healthcare workers by providing custom solutions that are specifically tailored to meet the unique and individual needs of each patient.

For those entering or considering a career in the healthcare field, gaining a thorough understanding of and mastering 3D printing technology offers a highly valuable and significant gateway to actively shaping and influencing the future landscape of medicine in meaningful ways.

Key Concepts and Theories

To truly and fully appreciate the vast scope and wide-ranging potential of 3D Printing, we must begin by carefully examining the underlying ideas, foundational theories, and conceptual models that guide its practical application and development.

In this blog post, we will take a detailed look at the fundamental concepts, core principles, and basic frameworks that support and drive its practice, helping us to better understand how and why 3D Printing works as it does.

What is 3D Printing in Healthcare?

3D printing, also known as additive manufacturing, is a revolutionary technology that fabricates three-dimensional objects layer by layer from precise digital models. In the healthcare context, it enables the creation of highly detailed, anatomically accurate medical devices, surgical models, implants, prosthetics, and even living tissues.

These objects are typically generated based on patient-specific medical imaging data such as CT scans or MRIs, ensuring that each printed item is customized to the unique anatomy and physiological characteristics of individual patients.

This process transforms complex digital information into tangible, physical models that enhance clinical practice by improving diagnosis accuracy, facilitating surgical planning, advancing medical education, and enabling personalized treatment. By offering a three-dimensional, patient-specific perspective, 3D printing bridges the gap between theoretical knowledge and real-world applications in medical care.

Areas of 3D Printing Application in Healthcare

Beyond the theoretical concepts and foundational principles, the true and profound impact of 3D printing technology becomes evident through its diverse and life-changing applications across the vast and ever-evolving healthcare sector.

In this discussion, we will thoroughly explore the key areas and specific fields where this innovative technology is already revolutionizing and transforming patient care in remarkable ways, ranging from detailed surgical planning to the creation of highly customized medical devices tailored to individual patient needs.

Anatomical Models

Three-dimensional printed replicas of organs, bones, or various other body parts serve as incredibly valuable tools for medical students, surgeons, and healthcare professionals alike. These highly detailed models greatly assist in visualizing and gaining a deeper understanding of complex anatomical structures that can be difficult to comprehend through textbooks or traditional images alone.

Additionally, they provide an excellent means for rehearsing and practicing surgical procedures in a realistic and hands-on manner. Furthermore, these models play a crucial role in effectively communicating with patients, helping them to better understand their specific medical conditions and the treatments being proposed.

Patient-Specific Implants and Prosthetics

Traditional ‘one-size-fits-all’ medical devices are frequently less efficient, less comfortable, and often do not meet the unique anatomical and functional requirements of individual patients. Thanks to advances in 3D printing technology, implantable devices and prosthetic limbs can now be custom-designed and precisely tailor-made to fit the exact contours, dimensions, and specific functional needs of each patient.

This highly personalized approach significantly boosts the overall success rate of various treatments and medical procedures, while also greatly enhancing patient comfort, mobility, and overall satisfaction with the medical devices they use throughout their recovery and daily activities.

Surgical Guides

Personalized surgical guides are meticulously designed and 3D printed to provide surgeons with highly accurate tools that assist in the precise execution of complex surgical procedures. By offering tailored guidance specific to each patient’s unique anatomy, these guides significantly help reduce the risk of intraoperative errors and enhance overall procedural efficiency.

This significant advancement in surgical technology ultimately plays a crucial role in contributing to much-improved clinical outcomes, thereby ensuring that surgeries are not only safer but also result in significantly faster recovery times for patients.

Bioprinting

An exciting and rapidly emerging frontier in the ever-evolving field of healthcare, bioprinting involves the innovative and groundbreaking use of living cells as ‘bio-inks’ to create and print highly complex tissues or even entire functional organs. This cutting-edge technology holds immense potential to revolutionize medical treatments and organ transplantation in the near future.

While this technology is still largely in the experimental stage, it holds tremendous potential for advancing regenerative medicine, improving the accuracy of drug testing, and possibly enabling organ transplantation in the future, revolutionizing how medical treatments are approached.

Medical Devices and Rapid Prototyping:

3D printing plays a crucial role in accelerating innovation within the medical device industry by enabling rapid prototyping processes. This technology allows new ideas and concepts to be quickly transformed into tangible physical models or parts, which can then be thoroughly tested, refined, and optimized for better performance.

As a result, the entire development cycle is significantly shortened, helping to reduce both time and production costs. Additionally, this approach supports the creation of highly personalized medical solutions tailored to the unique needs of individual patients, ultimately improving healthcare outcomes.

This multifaceted and dynamic role of 3D printing in healthcare significantly enhances patient care and medical education while simultaneously creating a wide array of specialized and highly rewarding career pathways. These opportunities are especially valuable for healthcare graduates who are eager to innovate, contribute cutting-edge solutions, and take on leadership roles within this rapidly expanding and evolving field.

Current Trends and Developments

3D printing in healthcare is an incredibly fast-growing and rapidly evolving field, with new and exciting developments emerging almost constantly. In this section, we will take an in-depth look at the most recent trends, covering everything from significant advancements in printing materials and cutting-edge bioprinting techniques to the expanding use and adoption of this innovative technology within various clinical settings.

We will carefully examine how these groundbreaking innovations are not only transforming the future landscape of medicine but also driving a growing demand for a new generation of highly skilled and specialized professionals who can effectively harness these technologies.

Advancements in Medical Education

3D printing has profoundly transformed medical education by providing healthcare students with hands-on, patient-specific anatomical models that replace traditional 2D images or less flexible anatomical resources. These tactile models, created from actual patient imaging data, allow students to better grasp complex anatomical relationships and pathological variations.

Studies have shown that medical students using 3D printed models score significantly higher in understanding congenital heart defects and other intricate anatomical conditions, compared to those using conventional learning tools.

Furthermore, 3D models enhance clinical thinking, increase learner confidence, and promote better problem-solving skills, especially when integrated with case-based or problem-based learning approaches.

These immersive educational experiences are cost-effective, accessible in resource-limited settings, and enable the study of rare diseases or pathologies that conventional models rarely represent. As a result, 3D printing is elevating the quality of healthcare training globally and better preparing graduates for real-world clinical challenges.

Customized Patient Care

Hospitals and research institutions are increasingly adopting 3D printing to deliver custom implants, surgical guides, and prosthetics tailored precisely to patient anatomies. This personalized approach improves surgical precision, reduces operation risks, and shortens recovery times.

For example, 3D printed models have been widely used for pelvic fracture surgery planning, allowing surgeons to rehearse the procedure, anticipate challenges, and optimize implant placement. Such tailored surgical planning has correlated with fewer complications and faster patient recovery.

Orthopedic advancements have also made significant strides with the introduction of FDA-approved patient-specific implants, such as talus spacers. These innovative implants are designed to fit the unique anatomy of each patient, providing a tailored approach to treatment.

Clinical follow-ups have demonstrated that these talus spacers offer remarkable benefits, including substantial reductions in pain and notable improvements in overall mobility and joint function. This personalized technology represents a major step forward in orthopedic care, enhancing patient outcomes and quality of life.

Moreover, 3D printing expedites clinical workflows by enabling point-of-care manufacturing, where hospitals can produce needed medical tools or devices onsite, reducing costs, wait times, and dependency on external suppliers.

These patient-specific solutions increasingly support specialties such as orthopedics, cardiovascular surgery, oncology, and dentistry, expanding the scope and impact of 3D printing in contemporary healthcare.

Bioprinting Breakthroughs

Bioprinting, an emergent frontier of 3D printing, focuses on the layer-by-layer fabrication of living tissues and organs using bioinks containing living cells. Though still largely in the experimental phase, bioprinting holds promise to solve critical challenges such as the global shortage of transplantable organs.

Recent progress in bioprinting has enabled the creation of organoids and tissue models used for drug testing and disease research, representing a more accurate, personalized alternative to animal testing. Researchers are developing bioprinted vascular grafts and heart valves with improved longevity and biocompatibility, which may drastically reduce repeat surgeries.

In the year 2025, the integration of advanced artificial intelligence technologies alongside the development of novel bioinks possessing significantly enhanced properties continues to drive considerable improvements in bioprinting outcomes.

These advancements are steadily bringing the field closer to practical clinical applications, including the promising areas of organ regeneration and highly personalized medicine tailored to individual patient needs.

As this innovative and rapidly evolving field progresses, it is generating a wide range of interdisciplinary career opportunities specifically for healthcare graduates who have a keen interest in bioengineering, regenerative medicine, and translational research, enabling them to contribute to cutting-edge medical breakthroughs.

Career Opportunities for Healthcare Graduates in 3D Printing

The rapid and widespread expansion of 3D printing technology within the healthcare sector has led to the creation of a wide variety of diverse and highly specialized career paths. These new opportunities uniquely combine in-depth medical knowledge with the most advanced and cutting-edge technological developments.

Graduates in healthcare fields who take the initiative to acquire relevant and up-to-date skills in 3D printing and related technologies can strategically position themselves in the job market for roles that seamlessly blend clinical expertise, biomedical engineering, innovative research, and technological innovation. Some of the key and most promising career opportunities in this evolving field include:

3D Printing Specialists and Engineers

- Role: Operate and maintain advanced 3D printers with precision and expertise, ensuring optimal functionality and performance at all times. Design and meticulously prepare patient-specific anatomical models that accurately represent individual patient anatomy. Develop and create customized surgical aids, prosthetics, and a wide range of specialized medical devices tailored to meet the unique needs of each patient, enhancing surgical outcomes and patient care.

- Involvement: Work in close collaboration with clinicians and medical professionals to accurately translate complex medical imaging data into detailed, high-quality printable models. Take an active role in troubleshooting any issues that arise during the printing processes, ensuring smooth operation and minimal disruptions. Additionally, implement rigorous quality control measures to guarantee that the final printed models meet all required standards and specifications for clinical use.

- Skills Needed: Strong proficiency and hands-on experience with CAD software such as Materialise Mimics and SolidWorks, are essential. Additionally, expertise in medical imaging post-processing techniques is required to accurately interpret and manipulate medical images. A solid understanding of materials science, particularly as it applies to medical devices and biocompatible materials, is also important. Furthermore, comprehensive knowledge of regulatory standards, including but not limited to ISO 13485, is necessary to ensure compliance in the design and manufacturing process.

- Example: Biomedical Engineers working in hospitals play a crucial role in overseeing comprehensive 3D printing programs that focus on creating highly specialized, patient-specific surgical guides and implants. They are responsible for managing complex workflows and coordinating multiple research and development projects to ensure the effective integration of these advanced technologies into clinical practice.

Clinical Application Specialists

- Role: Serve as a vital link bridging the gap between clinical teams and 3D printing operations by strategically aligning the use of advanced technology with the overarching goals of patient care and treatment outcomes. This position ensures seamless integration of innovative 3D printing solutions to support and enhance clinical practices, ultimately improving patient experiences and healthcare delivery.

- Responsibilities: Actively facilitate and promote multidisciplinary collaboration among various healthcare professionals, ensuring effective communication and teamwork. Provide comprehensive education and training to healthcare teams on the numerous benefits and applications of 3D printing technology. Assist in the seamless integration of 3D printed solutions into existing treatment workflows, helping to optimize patient care and clinical outcomes.

- Value Add: Significantly enhances the adoption and widespread use of 3D-printed medical solutions by thoroughly ensuring their clinical relevance and prioritizing patient safety at every stage of development and implementation.

Biomedical Researchers and Scientists

- Role: Innovate and create new advanced printing materials, optimize and enhance bioprinting processes for improved precision and efficiency, and develop cutting-edge tissue engineering applications for medical and research purposes.

- Research Focus: Concentrating on the latest advancements in the field of bioprinting living tissues, enhancing the biocompatibility of materials used in medical applications, and developing innovative prototypes for new medical devices. This research aims to push the boundaries of current technology by integrating cutting-edge techniques to improve the functionality and safety of biomedical products.

- Career Path: Typically associated with academic institutions, innovative biotech startups, or large corporate research and development units that specialize in translational medicine. These career paths often involve working at the cutting edge of scientific discovery and applying research findings to develop new medical treatments and technologies. Professionals in this field may collaborate across disciplines, contributing to both fundamental science and practical applications aimed at improving patient outcomes and advancing healthcare solutions.

Medical Device Developers and Rapid Prototyping Engineers

- Role: Utilize advanced 3D printing technology to enable rapid prototyping and efficient production of highly customized medical devices, significantly accelerating the innovation cycles within the healthcare industry. This approach allows for quicker design iterations and faster delivery of tailored solutions to meet specific patient needs.

- Contribution: Design and rigorously test innovative device concepts, continuously refine and improve solutions based on detailed clinician feedback, and actively contribute to the preparation and submission of comprehensive FDA and CE regulatory documentation to ensure compliance and approval.

- Industry: Positions available in medical device manufacturing companies that utilize advanced additive manufacturing technologies to produce bespoke, custom-tailored, or low-volume parts with high precision and efficiency. These roles focus on innovative production techniques to meet the specific needs of medical applications where traditional manufacturing methods may fall short.

Quality Control and Regulatory Specialists

- Role: Take responsibility for ensuring that all printed medical products consistently meet the necessary quality and safety standards by conducting thorough and rigorous testing procedures as well as detailed compliance audits. This role involves meticulously verifying that every aspect of the printed products adheres to established regulations and guidelines to guarantee their reliability and safety in medical applications.

- Importance: Effectively navigate complex regulatory frameworks such as FDA 21 CFR part 820 and ISO 13485, ensuring full compliance throughout all stages of the product lifecycle. Skillfully draft comprehensive quality documentation that meets stringent regulatory requirements and industry standards. Additionally, meticulously oversee validation protocols to guarantee that all processes and products consistently adhere to established quality and safety criteria.

- Background: This role frequently demands a comprehensive understanding of medical device regulations, paired with a deep technical expertise in additive manufacturing processes. Candidates are expected to have a solid grasp of regulatory requirements alongside practical knowledge of the technologies involved in additive manufacturing.

Educational Technologists and Medical Trainers

- Role: Develop comprehensive medical training programs and design detailed educational materials that incorporate the use of advanced 3D printed anatomical models to enhance learning and understanding.

- Goal: To significantly enhance healthcare education by providing highly realistic simulation tools combined with immersive hands-on learning experiences that are specifically tailored to meet the unique needs of both students and professionals in the healthcare field.

- Opportunity: Numerous roles are available in a variety of settings, including academic institutions, medical simulation companies, and hospital education departments. These positions offer diverse opportunities for professionals interested in advancing education and training within the healthcare industry.

Key Skills and Qualifications

To truly excel and stand out in these important healthcare roles, graduates should focus on developing and building a wide range of essential competencies, including:

- Extensive expertise in using advanced CAD (Computer-Aided Design) tools and specialized medical imaging software, demonstrating a deep understanding of their functionalities and applications in various professional settings. This includes proficiency in creating detailed 3D models, analyzing complex medical images, and integrating software capabilities to enhance diagnostic and design processes.

- Comprehensive understanding of various 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and advanced bioprinting techniques. This knowledge encompasses the principles, materials, applications, and advantages of each technology, enabling effective selection and utilization in diverse manufacturing and research environments.

- Extensive familiarity with the field of materials science, particularly as it relates to biocompatible and implantable materials used in medical applications. This includes a deep understanding of the properties, behavior, and interactions of various materials designed to safely integrate with biological systems over extended periods.

- Comprehensive knowledge of regulatory frameworks and quality management systems specifically relevant to the development, manufacturing, and distribution of medical devices. This includes understanding the various international standards, compliance requirements, and industry best practices essential for ensuring the safety, efficacy, and reliability of medical devices throughout their lifecycle.

- Effective and strong interdisciplinary communication that seamlessly combines and integrates both clinical and engineering terminologies is essential for fostering collaboration and understanding between professionals from these diverse fields. This type of communication bridges the gap between clinical insights and engineering principles, enabling more comprehensive and innovative solutions to complex problems.

Leading Employers and Opportunities

Several innovative companies and leading hospitals are currently at the forefront of advancing 3D printing technology within the healthcare industry, playing a pivotal role in revolutionizing patient care and medical research.

These organizations are actively offering a wide range of internship programs and career opportunities for individuals interested in contributing to this cutting-edge field, allowing them to gain hands-on experience and develop specialized skills in 3D printing applications for medicine.

- Hospitals that have dedicated 3D printing laboratories, such as UPMC Presbyterian, located in Pittsburgh, are actively seeking to hire highly skilled biomedical engineers as well as specialists who have expertise in 3D printing technology. These institutions recognize the importance of advanced 3D printing capabilities in improving patient care and medical research, which drives their ongoing recruitment efforts.

- Medical technology companies such as 3D Systems and Axial3D provide a wide range of roles that encompass engineering, clinical application, and research fields. These companies offer diverse opportunities for professionals interested in developing cutting-edge medical devices, improving clinical procedures, and conducting innovative research to advance healthcare technology. This variety of roles supports collaboration among engineers, clinicians, and researchers to drive advancements in medical solutions.

- Startups and bioprinting firms that specialize in tissue engineering and regenerative medicine are continuously expanding at a rapid pace. These companies are seeing significant growth and development, largely due to the valuable expertise and innovative skills brought in by graduates from healthcare technology programs. The influx of knowledgeable professionals is playing a crucial role in advancing the capabilities and reach of these cutting-edge firms.

This career-focused overview thoroughly equips healthcare graduates with a detailed and clear understanding of the rapidly expanding professional landscape that is being significantly transformed and enabled by the innovative advancements in 3D printing technology within the field of medicine.

Training and Certifications for Healthcare Graduates in 3D Printing

To truly thrive and excel in the rapidly evolving and continuously advancing field of 3D printing within the healthcare industry, obtaining specialized training and professional certifications is essential. These comprehensive programs are designed to equip graduates with a robust set of technical skills, in-depth clinical knowledge, and a thorough understanding of regulatory requirements.

This combination prepares them to operate advanced 3D printing technologies efficiently and confidently, while also empowering them to innovate and improve patient care outcomes in meaningful ways.

Specialized Courses and Certificates

- Certificate Course in Medical Imaging, 3D Modeling, and 3D Printing offered by Medvarsity

- Accredited by the prestigious British Accreditation Council (BAC), this comprehensive course thoroughly covers the process of converting patient imaging data into detailed and accurate 3D models. Participants will gain hands-on experience using advanced software tools such as 3D Slicer and Autodesk Meshmixer, which are essential for medical imaging and 3D model creation.

- Emphasizes the important clinical applications specifically designed for surgical planning as well as for developing highly personalized treatment approaches tailored to each patient’s unique medical needs and conditions.

- Offers extensive hands-on experience with a wide range of 3D printing technologies and diverse materials, allowing participants to gain practical knowledge and skills in the field.

Graduates receive an official certification that thoroughly validates their skills and expertise in the specialized field of medical 3D printing design and its precise execution. This certification serves as a formal recognition of their comprehensive knowledge and practical abilities in creating and implementing advanced 3D printing solutions within the medical industry.

- Medical 3D Printing and Visualization Specialist Certificate (Clarkson College)

- Specifically designed and carefully tailored for imaging professionals as well as healthcare practitioners who are dedicated to providing the highest quality care.

- Focuses comprehensively on the entire workflow, starting from medical imaging segmentation and extending through quality assurance processes, as well as addressing all relevant regulatory considerations. This approach ensures a thorough understanding and management of each stage involved in the imaging workflow.

Offers an extensive and thorough understanding of additive manufacturing processes, with a particular focus on their application in real-world patient care scenarios. This approach significantly enhances practical knowledge and improves clinical applications, ensuring that healthcare professionals are better equipped to utilize these advanced manufacturing techniques effectively in their medical practice.

- Postgraduate Certificate in 3D Printing for Medical Applications

- Advanced academic programs provide extensive and in-depth knowledge in additive manufacturing, specifically designed and tailored to drive innovations in the healthcare sector. These programs focus on equipping students with comprehensive expertise that addresses the unique challenges and opportunities found in medical applications.

These advanced courses frequently build upon foundational degrees in biomedical sciences or engineering fields, providing a deeper and more comprehensive understanding. They emphasize not only theoretical knowledge but also practical skills, with a strong focus on integrating cutting-edge research findings into clinical applications and healthcare settings.

- 3D Printing Certificate Course Online (IAP Career College)

- Fully online, self-paced course covering fundamentals of additive manufacturing, design optimization, material science, and certification processes.

- Suitable for beginners and professionals seeking to expand expertise.

Opportunity to earn a widely recognized and valuable certificate that can significantly enhance your resume and support successful career transitions. This credential serves as an important asset to showcase your skills and knowledge to potential employers.

- Hands-On Workshops and Practical Training

- Universities like the University of Szeged offer intensive physical workshops on 3D printing and its medical applications, including hands-on sessions for mastering printer operation and clinical model creation.

- Training in Regulatory and Quality Compliance

- Specialized modules or courses on FDA regulations, ISO standards (e.g., ISO 13485), and quality assurance practices pertinent to 3D printed medical devices are critical for roles in manufacturing and clinical application.

Partnering with Healthcare Institutions

- Healthcare graduates are strongly encouraged to actively seek out internship opportunities or collaborative projects with pioneering hospitals and advanced laboratories that offer specialized 3D printing services. Engaging with these cutting-edge institutions provides invaluable hands-on experience and exposure to the latest technologies in medical 3D printing, significantly enhancing professional skills and career prospects.

- Gaining practical experience in a clinical environment significantly enhances one’s understanding of patient-specific needs and the complexities of multidisciplinary workflows. This hands-on exposure allows individuals to grasp the nuances of patient care more effectively and appreciate the collaborative efforts required among various healthcare professionals to deliver optimal outcomes.

- Leading hospitals and major companies frequently offer specialized training programs, comprehensive workshops, and immersive residency opportunities that are specifically focused on the application of 3D printing technology within the healthcare sector. These educational initiatives are designed to equip medical professionals and industry experts with in-depth knowledge and practical skills related to the innovative use of 3D printing in medical treatments and healthcare solutions.

Benefits of Certification and Training

- Career Advancement: Validates and highlights professional expertise, significantly distinguishing candidates in an increasingly competitive and challenging job market. This recognition enhances their opportunities for promotion, opens doors to new career paths, and supports sustained long-term career growth and development.

- Technical Mastery: Develops an exceptionally high level of proficiency and advanced expertise in utilizing CAD tools with precision, processing complex medical imaging data accurately, and skillfully operating state-of-the-art 3D printers along with all related equipment in a highly effective and efficient manner.

- Regulatory Knowledge: Equips healthcare professionals with the essential skills and comprehensive understanding needed to effectively navigate the increasingly complex landscape of medical device regulations, ensuring full compliance and prioritizing patient safety at every stage of the process.

- Innovation Readiness: Thoroughly equips graduates with the essential skills and knowledge necessary to actively contribute to cutting-edge research and development efforts in the fields of bioprinting, advanced device design, and the rapidly evolving area of personalized medicine. This preparation enables them to drive innovation and make meaningful advancements in these specialized disciplines.

Through comprehensive and structured education combined with hands-on real-world exposure, healthcare graduates are equipped to confidently enter the workforce and take on leadership roles in the rapidly evolving, technology-driven future of medical care that is increasingly empowered and transformed by innovative 3D printing technologies.

FAQs

What is the role of 3D printing specialists in healthcare?

3D printing specialists are highly skilled professionals who operate advanced 3D printers, meticulously create and adjust detailed digital models, and work closely with clinicians to accurately meet patient-specific printing requirements.

Their expertise is crucial for successfully integrating 3D printing technology into clinical workflows, ensuring stringent quality control measures are followed, and maintaining the optimal performance of equipment within hospitals or medical device companies. These specialists play a vital role in bridging the gap between technology and healthcare, contributing significantly to improved patient outcomes through customized medical solutions.

Can 3D printing improve medical education?

3D printed anatomical models offer highly realistic and interactive, hands-on learning experiences that significantly enhance the comprehension of complex human anatomy. These models allow students and medical professionals to visualize and explore intricate anatomical structures tangibly.

Additionally, they greatly improve surgical training by providing the opportunity to practice procedures using patient-specific models tailored to individual cases. This personalized approach to training has been demonstrated to lead to a reduction in errors during actual surgeries in the operating room, ultimately contributing to better patient outcomes.

What are bioprinting engineers?

Bioprinting engineers are highly specialized professionals who focus on the innovative process of creating living tissues and fully functional organs by precisely printing with bioinks that contain living cells. Their important work serves as a critical bridge between the fields of biology and engineering, combining scientific knowledge and technical skills to push the boundaries of medical science.

This cutting-edge technology plays a vital role in advancing regenerative medicine, improving the accuracy and efficiency of drug testing, and developing groundbreaking solutions for future organ transplantation technologies that have the potential to save countless lives.

How can healthcare graduates prepare for careers in 3D printing?

Graduates should aim to develop a comprehensive set of skills that includes proficiency in CAD software, a thorough understanding of biomedical engineering principles, expertise in medical imaging conversion techniques, in-depth knowledge of materials science, and familiarity with relevant regulatory frameworks governing the industry.

Gaining practical experience through internships, obtaining specialized certifications, and engaging in hands-on training specifically focused on 3D printing technologies significantly accelerates both entry into the field and long-term success within this rapidly evolving industry.

Which healthcare sectors benefit most from 3D printing?

Orthopedics, dentistry, cardiovascular surgery, oncology, and pediatric medicine all benefit significantly from the widespread demand for highly customized implants, prosthetics, surgical guides, and detailed anatomical models. These specialized tools and devices play a crucial role in enhancing patient-specific care by allowing medical professionals to tailor treatments to the unique anatomical and physiological needs of individual patients, thereby improving outcomes and overall healthcare quality.

In Conclusion

3D printing is revolutionizing the healthcare industry by enabling personalized, precise, and innovative approaches to medical treatment, education, and device development. For healthcare graduates and students, this emerging technology is not only a powerful tool but also a gateway to future-proof careers that blend clinical expertise with cutting-edge engineering.

By acquiring relevant skills in 3D printing software, materials, and clinical applications, graduates can position themselves at the forefront of this healthcare transformation. Embracing 3D printing opens doors to specialized roles such as clinical application specialists, biomedical researchers, and medical device developers, all contributing to improved patient outcomes and medical innovations.

Educators and career counselors must fully recognize and understand the rapidly growing influence of this technology to provide effective guidance and support to healthcare professionals, helping them successfully navigate and thrive in their future career paths and professional development opportunities.

Ultimately, 3D printing is revolutionizing and shaping the future of healthcare in profound ways—countless opportunities are emerging for individuals and organizations who are prepared to innovate, continuously learn, and take on leadership roles in this rapidly evolving field.

Discover more from Skill to Grow

Subscribe to get the latest posts sent to your email.